TREVISAN MACHINE TOOL, LLC

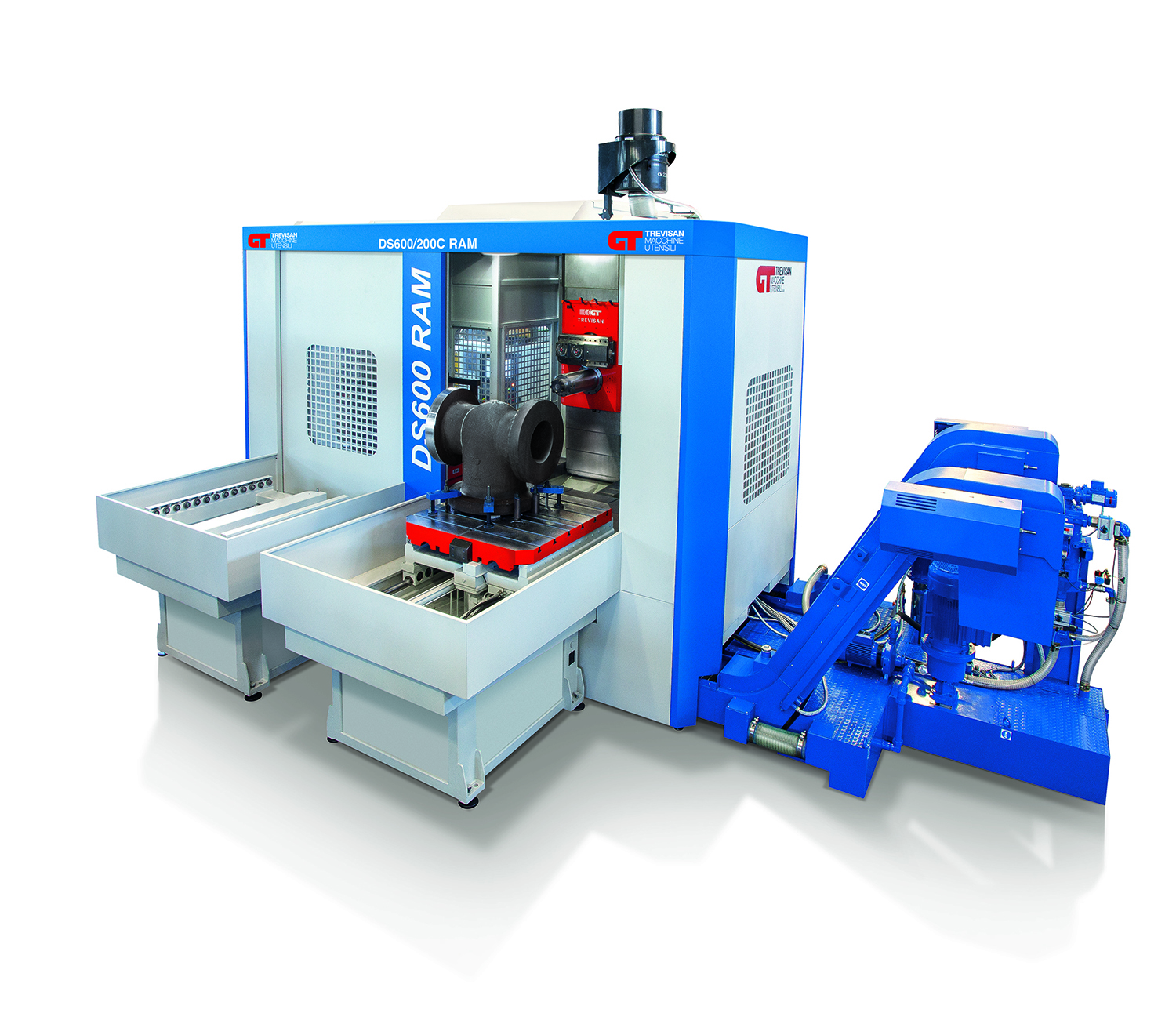

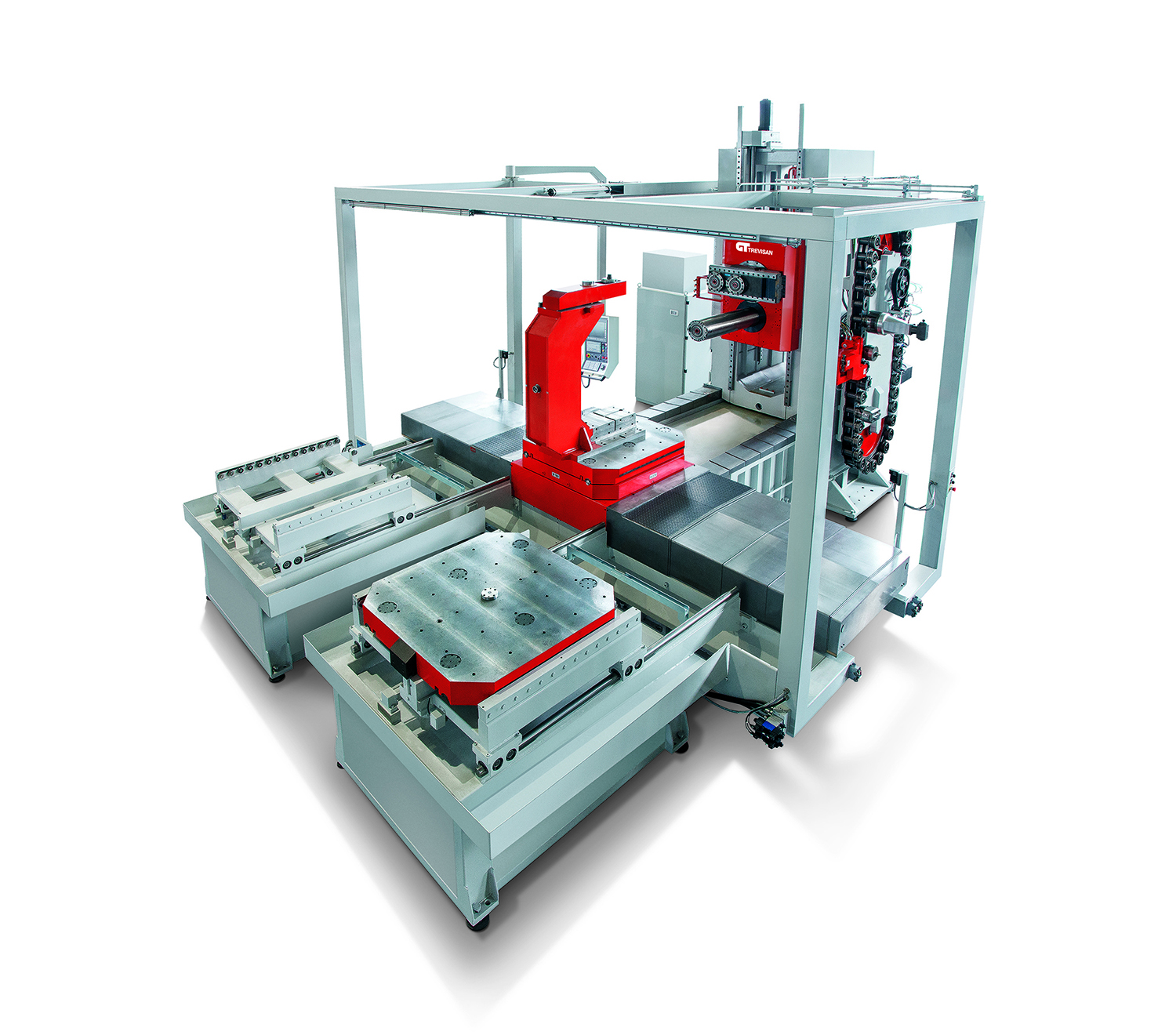

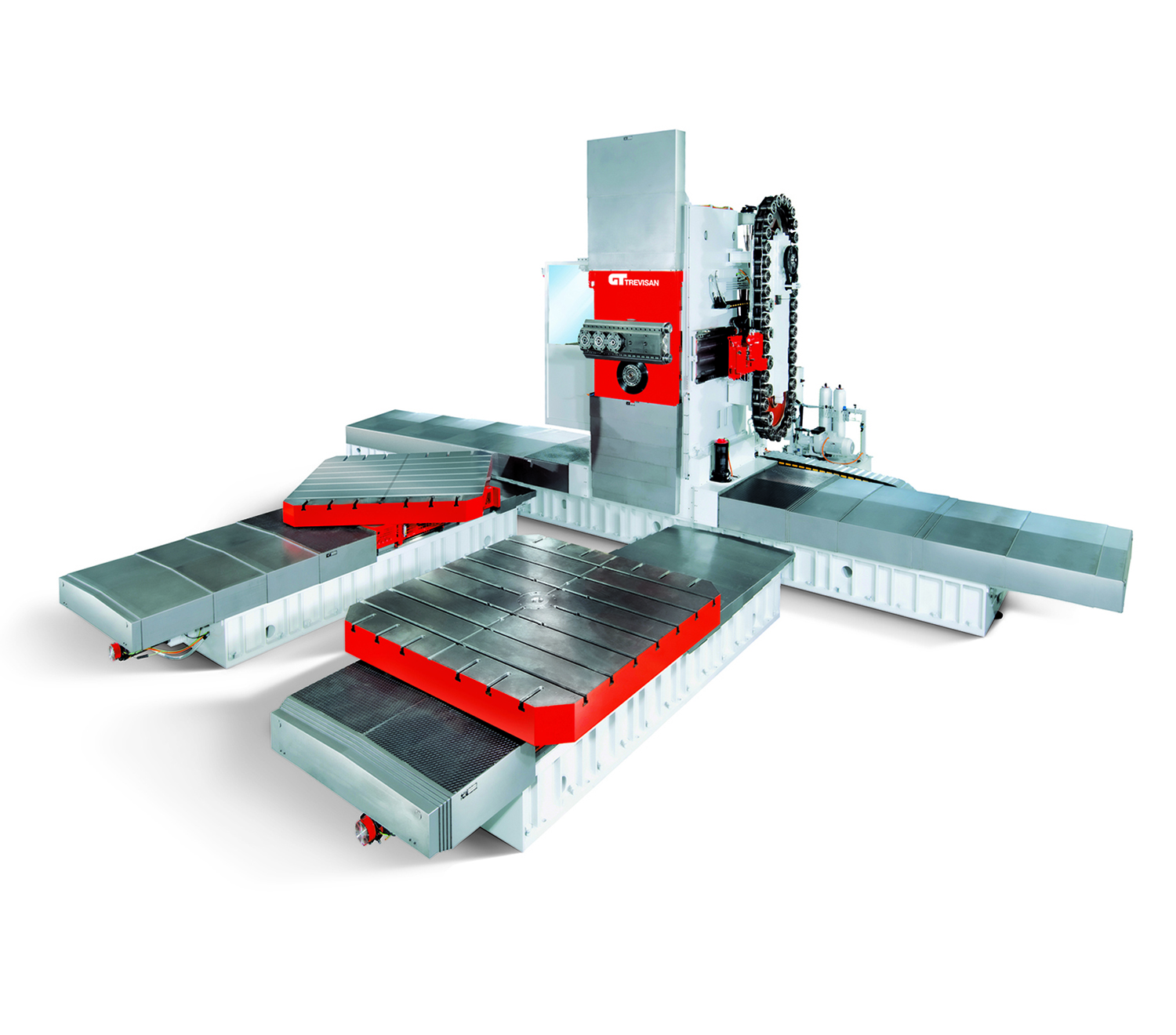

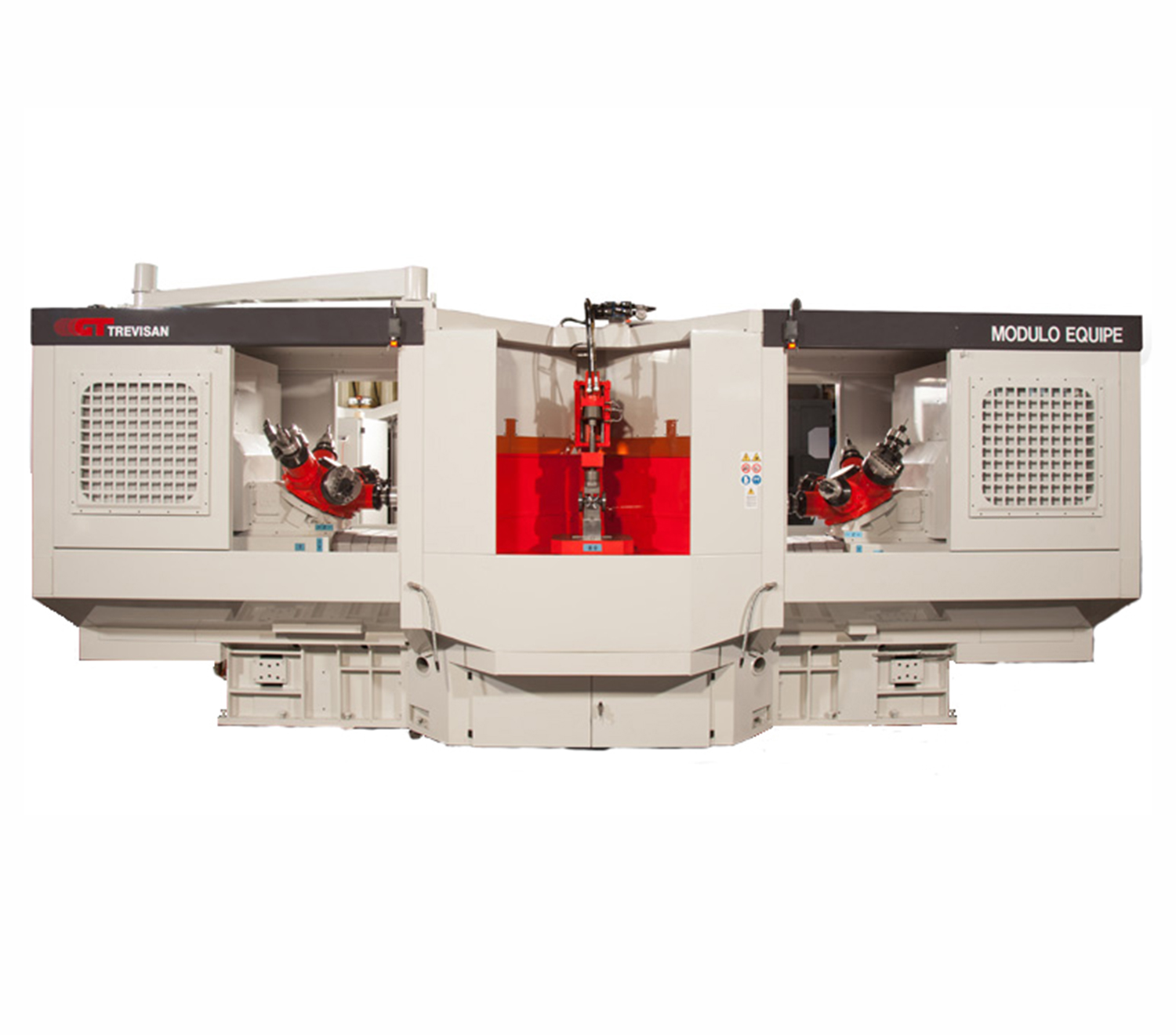

As the production and quality requirements become more demanding every day, Trevisan, with over 50 years of experience, has worked together with our customers to meet these demands. Trevisan offers a full line of horizontal U-axis machine centers with contour head capabilities up to 3 meters in diameter as well as a complement of solutions for our customers other demanding requirements.

Trevisan is a pioneer in the contour head development and has specialized in this type machine for many years now. Whether your goal is reduced cycle times, eliminating changeover time, Quality improvement, reduced material handling, part processing that reduces the amount of floor space required to produce your products, or all of the above, Trevisan has the solution for you.

MACHINES

Copyright © Tomel Machine Tool Services, LLC

All Rights Reserved